Hebei Xinao Technology Co., Ltd

EPS Raw Materials

EPS Raw Materials

EPS Raw Materials: Understanding Their Importance and Applications

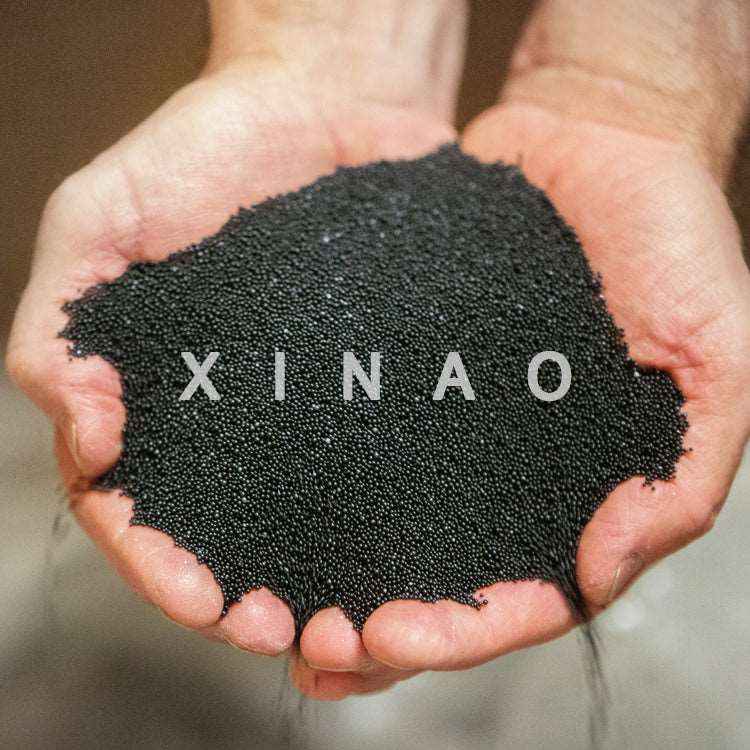

EPS Raw Materials are essential components in various industries, particularly in packaging, construction, and manufacturing. Expanded Polystyrene (EPS) is a lightweight, rigid, and closed-cell foam material that provides excellent insulation and cushioning properties. It is created by polymerizing styrene into a granular foam, which is then expanded and molded into products. The versatility of EPS Raw Materials makes them indispensable for numerous applications. Let's delve deeper into the specifics of EPS Raw Materials, their properties, and their uses.

The manufacturing process of EPS Raw Materials begins with the polymerization of styrene, a liquid hydrocarbon that is commercially produced from petroleum. This process creates polystyrene beads, which are then heated, causing them to expand. As these beads expand, they form foam that is stable, durable, and effective in a wide range of uses. This unique structure is what gives EPS its advantageous properties, making it a top choice for many businesses.

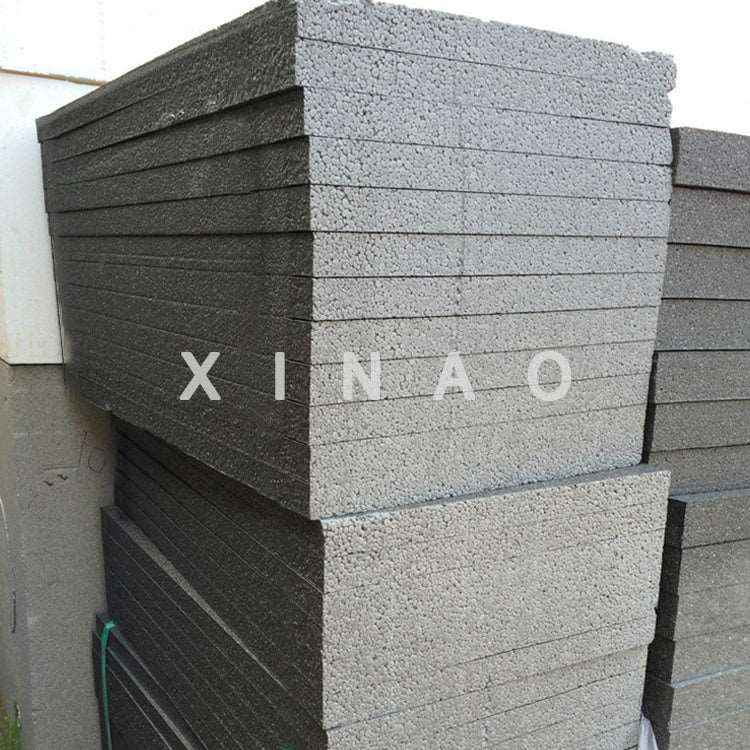

One of the key characteristics of EPS Raw Materials is their exceptional insulating properties. EPS offers excellent thermal insulation, which is why it is commonly used in the construction of energy-efficient buildings. The material helps to reduce energy consumption by providing a barrier against heat transfer, keeping interiors warm in winter and cool in summer.

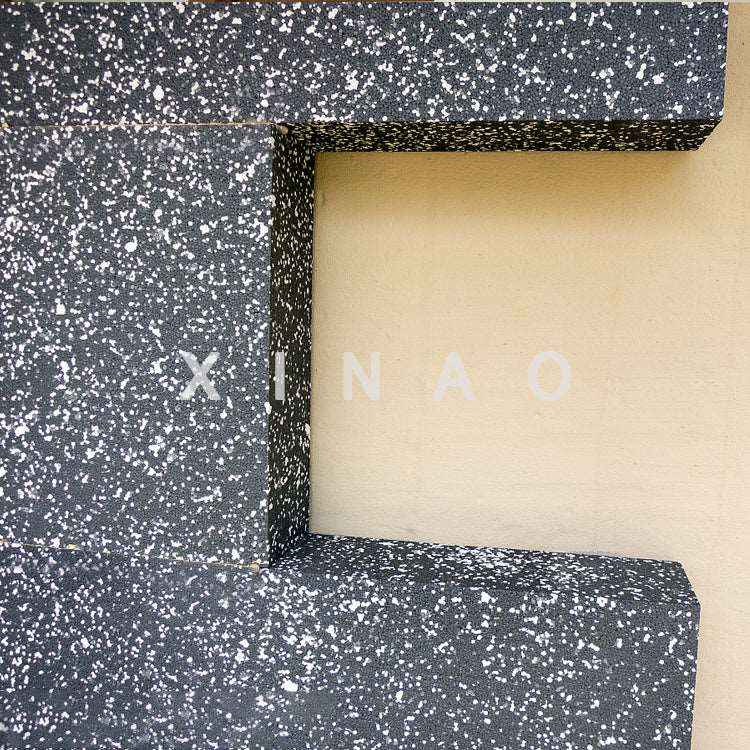

Additionally, EPS Raw Materials are widely used in the packaging industry. They provide reliable shock absorption and protection for fragile items, ensuring that products arrive at their destinations in perfect condition. From electronics to food packaging, EPS is preferred for its lightweight yet sturdy nature, allowing manufacturers to minimize shipping costs while maintaining product safety.

In the realm of construction, EPS Raw Materials play a significant role in foundations, walls, and other structural components. They are often utilized in insulated concrete forms (ICFs) and Structural Insulated Panels (SIPs), promoting speedy construction without compromising on insulation standards. This is particularly valuable in modern eco-friendly building practices where energy efficiency is of utmost concern.

The environmental impact of EPS Raw Materials has garnered attention in recent years. While EPS is recyclable, there is still debate over its biodegradability. Awareness campaigns about recycling EPS have increased, encouraging consumers and companies alike to consider sustainable practices. Innovations continue to emerge, aiming to enhance the recyclability and environmental friendliness of EPS products.

EPS Raw Materials are also favored in the agricultural sector. The material is used for seedling trays and plant pots, providing an eco-friendly option for growers. The lightweight nature of EPS makes it easy to handle, while its insulation properties promote healthy plant growth.

Moreover, EPS Raw Materials are used in crafting and DIY projects. The foam can be easily cut, shaped, and painted, making it a go-to choice for artists and crafters. Its versatility in design and application appeals to hobbyists and professionals alike.

Despite its many benefits, it is crucial to handle EPS Raw Materials responsibly. The sheer volume of EPS waste generated can lead to environmental challenges if not managed properly. Engaging in recycling programs and promoting responsible usage are steps that industry players can take to mitigate negative impacts.

In summary, EPS Raw Materials are crucial for diverse applications due to their insulation and cushioning properties. From construction to packaging and agriculture, the versatility of EPS emphasizes its importance in modern industry. As the market continues to evolve, embracing sustainability in the use of EPS Raw Materials will be key to ensuring that this valuable resource serves future generations effectively.

Share