Hebei Xinao Technology Co., Ltd

EPS Shape Moulding Machine

EPS Shape Moulding Machine

EPS Shape Moulding Machine

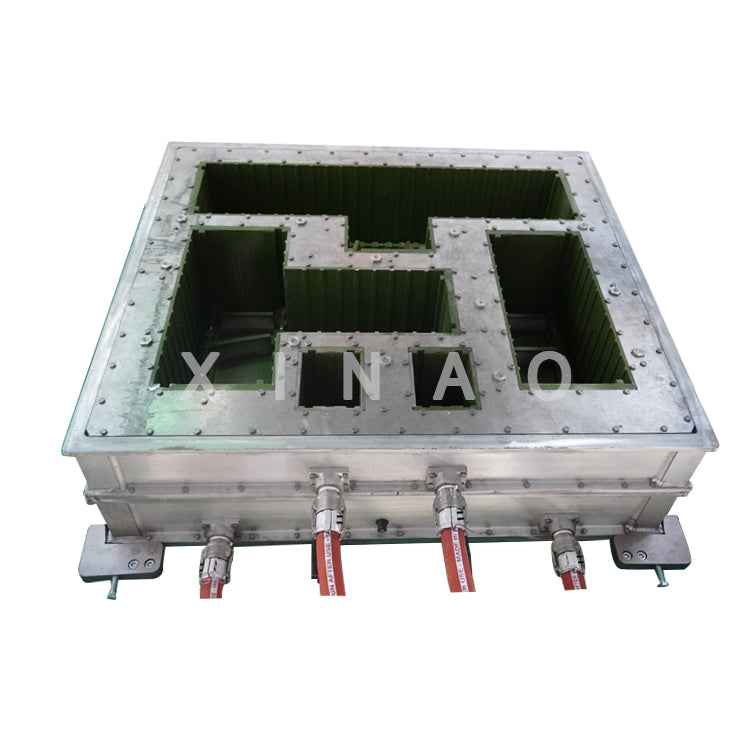

The EPS Shape Moulding Machine is a revolutionary piece of equipment designed for efficient and precise manufacturing of expanded polystyrene (EPS) products in various shapes and sizes. This machine is ideal for producing goods such as packaging materials, insulation panels, and decorative elements, significantly enhancing production efficiency while maintaining high-quality standards.

In the world of manufacturing, particularly in the EPS industry, the capability to mold specific shapes and sizes is crucial. The EPS Shape Moulding Machine is engineered to meet these needs through advanced technology and user-friendly features. Its versatility allows it to cater to both small-scale operations and large production facilities, adapting to different production demands seamlessly.

One of the key aspects of the EPS Shape Moulding Machine is its ability to maintain high precision throughout the molding process. This is achieved through carefully controlled temperature and pressure settings, allowing manufacturers to produce products that adhere to exact specifications. The machine employs a sophisticated heating system that ensures uniform temperature distribution, preventing any cold spots that could lead to inconsistencies in the final product.

Moreover, the EPS Shape Moulding Machine features a user-friendly interface that allows operators to easily configure settings and monitor the entire production process. This not only reduces the learning curve for new users but also minimizes the potential for human error, further enhancing the reliability of the output.

Manufacturers can also benefit from the machine's energy efficiency. The advanced technology implemented in the EPS Shape Moulding Machine reduces energy consumption, leading to cost savings over time. This is especially important in today's market, where energy costs can significantly affect overall production budgets. The environmentally-friendly design of the machine helps companies reduce their carbon footprint while improving their bottom line.

Additionally, the EPS Shape Moulding Machine supports the use of recycled EPS materials, contributing to a more sustainable manufacturing process. This feature not only helps reduce waste but also appeals to environmentally conscious consumers who prefer products made from recycled materials.

Safety is another priority in the design of the EPS Shape Moulding Machine. Equipped with various safety features, including emergency shut-off systems and protective guards, the machine ensures a safe working environment for all operators. Regular maintenance schedules are also facilitated through clear access to all necessary components, helping to prolong the lifespan of the equipment.

In terms of product diversity, the EPS Shape Moulding Machine can handle a wide range of projects, from simple geometric shapes to complex and customized designs. This adaptability is a significant advantage for businesses looking to expand their offerings without investing in multiple machines. The ability to quickly switch between different molds allows for rapid production runs and customization, responding to market demands efficiently.

Furthermore, the EPS Shape Moulding Machine is compatible with various mold designs, providing manufacturers with the flexibility to create unique products tailored to customer specifications. This custom-molding capability is instrumental in sectors such as construction, where specific insulation or packaging demands can vary greatly from project to project.

While considering investment in an EPS Shape Moulding Machine, it's essential to factor in the total cost of ownership. Beyond the initial purchase price, prospective buyers should assess ongoing operational costs, maintenance requirements, and potential energy savings. With the right machine, companies can achieve significant returns on their investment through increased productivity, reduced waste, and improved product quality.

In conclusion, the EPS Shape Moulding Machine stands out in the manufacturing landscape as a pivotal tool that meets the complex demands of today's industrial environments. With a combination of precision, efficiency, safety, and sustainability, this machine is an asset to both established manufacturers and those new to the EPS market. Investing in an EPS Shape Moulding Machine not only enhances production capabilities but also positions companies to thrive in a competitive landscape focused on innovation and quality.

Share